- Universal Pipette Tips

- Low Retention Pipette Tips

- LTS Pipette Tips

- 5ml/10ml Tips

- Robitic Pipette Tips

- Gel Loading Tip

- Serological Pipette

- Cell Culture Flask

- Cell Culture Plate

- Cell Culture Dish

- Petri Dish

- Square Media Bottle

- Erlenmeyer Flask

- Cell Factory System

- Cell Factory accessories

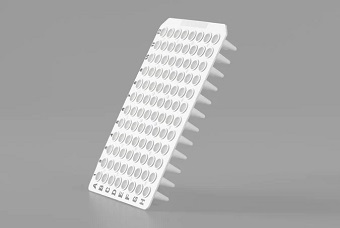

- 96-Well Non-Skirted PCR Plates

- 96-Well Half Skirt, Fit ABI PCR Plates

- 96-Well Half Skirt, Fit Biorad/Roche PCR Plates

- 96-Well Sub Semi-skirt/High-skirt, Fit ABI PCR Plates

- 96-Well Full-skirt PCR Plates

- 40ul 384-Well PCR Plate

- 8-Strip PCR Tubes

- PCR Tubes with Attached Flat Caps

- PCR Sealing Film

- 96 Well Plate

- 96 Well Microplate Plate Deep-Well Tip Combs

- Deep Well I-plate

- 8 Strip Tip Deep-Well Tip Deep-Well Tip Combs

- 10ul Standard 32mm Universal Pipette Tips

- 10ul Extra Long 46mm Universal Pipette Tips

- 10ul Extra Long, Thin and Sharp 46mm Universal Pipette Tips

- 200ul Standard Universal Pipette Tips

- 200ul Standard Wider Universal Pipette Tips

- 200ul Extra Long or 300ul Universal Pipette Tips

- 200 Super Long Universal Pipette Tips

- 1000ul Standard Universal Pipette Tips

- 1000ul Extra Long or 1250ul Universal Pipette Tips

- 1000 Medium Long Universal Pipette Tips

- 10ul Standard 32mm Low Retention Pipette Tips

- 10ul Extra Long 46mm Low Retention Pipette Tips

- 10ul Extra Long, Thin and Sharp 46mm Low Retention Pipette Tips

- 200ul Standard Low Retention Pipette Tips

- 200ul Standard Wider Low Retention Pipette Tips

- 200ul Ultra Long or 300ul Low Retention Pipette Tips

- 200 Super Long Low Retention Pipette Tips

- 1000ul Standard Low Retention Pipette Tips

- 1000ul Extra Long or 1250ul Low Retention Pipette Tips

- 1000 Medium Long Low Retention Adjustable Spacer Multichannel Pipette Tips

- SPTS01 1ml Serological Pipette

- SPTB01 Serological Pipette 1 ML

- SPTS02 2ml Serological Pipette

- SPTB02 Serological Pipetman

- SPTS05 5ml Serological Pipette

- SPTB05 Serological Pipette 5ml

- SPTS10 10ml Serological Pipette

- SPTS10A Plastic Pipette 10ml

- SPTB10A 25ml Serological Pipette

- SPTB10 25ml Serological Pipette

- SPTS25 50ml Serological Pipette

- SPTB25 Serological Pipette 25ml

- SPTS50 50ml Serological Pipette

- SPTB50 Plastic Serological Pipettes

- CL-F025P T25 Cell Culture Flask

- CL-F075P T75 Cell Culture Flask

- CL-F175P T175 Cell Culture Flask

- CL-F225P T225 Cell Culture Flask

- CL-F025P Cell Culture Flask

- CL-FT025P Cell Culture Flask

- CL-F025V Cell Culture Flask

- CL-FT025V Cell Culture Flask

- CL-F075P Cell Culture Flask

- CL-FT075P Cell Culture Flask

- CL-F075V Cell Culture Flask

- CL-FT075V Cell Culture Flask

- CL-F175P Cell Culture Flask

- CL-FT175P Cell Culture Flask

- CL-F175V Cell Culture Flask

- CL-FT175V Cell Culture Flask

- CL-P006 6 Well Cell Culture Plate

- CL-P012 12 Well Cell Culture Plate

- CL-P024 24 Well Cell Culture Plate

- CL-P048 48 Well Cell Culture Plate

- CL-P096 96 Deep Well Plate

- CL-P006 Cell Culture Plate

- CL-PT006 Cell Culture Plate

- CL-P012 Cell Culture Plate

- CL-PT012 Cell Culture Plate

- CL-P024 Cell Culture Plate

- CL-PT024 Cell Culture Plate

- CL-P048 Cell Culture Plate

- CL-PT048 Cell Culture Plate

- CL-P096 Cell Culture Plate

- CL-PT096 Cell Culture Plate

- CL-D035 35 Mm Cell Culture Dish

- CL-D060 6cm Cell Culture Dish

- CL-D100 10cm Cell Culture Dish

- CL-D035 Cell Culture Dish

- CL-DT035 Cell Culture Dish

- CL-D060 Cell Culture Dish

- CL-DT060 Cell Culture Dish

- CL-D100 Cell Culture Dish

- CL-DT100 Cell Culture Dish

- CL-D150 Cell Culture Dish

- CL-DT150 Cell Culture Dish

- SMB125T Square Media Bottle

- SMB250T Square Media Bottle

- SMB500T Square Media Bottle

- SMB1000T Square Media Bottle

- SMB125G Square Media Bottle

- SMB250G Square Media Bottle

- SMB500G Square Media Bottle

- SMB1000G Square Media Bottle

- EFC-125P Erlenmeyer Flask

- EFC-250P Erlenmeyer Flask

- EFC-500P Erlenmeyer Flask

- EFC-1000P Erlenmeyer Flask

- EFC-125V Erlenmeyer Flask

- EFC-250V Erlenmeyer Flask

- EFC-500V Erlenmeyer Flask

- EFC-1000V Erlenmeyer Flask

- EFG-125P Erlenmeyer Flask

- EFG-250P Erlenmeyer Flask

- EFG-500P Erlenmeyer Flask

- EFG-1000P Erlenmeyer Flask

- EFG-125V Erlenmeyer Flask

- EFG-250V Erlenmeyer Flask

- EFG-500V Erlenmeyer Flask

- EFG-1000V Erlenmeyer Flask

- EFBC-125P Erlenmeyer Flask

- EFBC-250P Erlenmeyer Flask

- EFBC-500P Erlenmeyer Flask

- EFBC-1000P Erlenmeyer Flask

- EFBC-125V Erlenmeyer Flask

- EFBC-250V Erlenmeyer Flask

- EFBC-500V Erlenmeyer Flask

- EFBC-1000V Erlenmeyer Flask

- PCRP-10NS 0.1ml Tube

- Unskirted PCRP-10NS-W Plate

- PCRP-20NS 0.2ml 96 Well Plate

- White PCRP-20NS-W Plates

- STSS-509CN 0.5ml Screw Cap Tubes

- STSS-509CR Screw Cap With O Ring

- STSS-509CB Self Standing Tube

- STSS-509CP Clear Tube With Cap

- STSS-509CY Clear Plastic Storage Tubes With Caps

- STSS-509CG Clear Plastic Tube With Lid

- STSS-509AM Acrylic Tube End Caps

- STSS-510CN 1.5ml Conical Tube

- STSS-510CR 1.5ml Cryotubes

- STSS-510CB 1.5ml Screw Cap Tubes

- STSS-510CP 1.5ml Polypropylene Tube

- STSS-510CY 1.5ml Microcentrifuge Tubes Sterile

- STSS-510CG 1.5ml Microfuge Tubes

- STSS-510AM 1.5ml Amber Tube

- STSS-511CN Screw Cap Tube

- STSS-511CR Screw Cap Tube

- STSS-511CB Screw Cap Tube

- STSS-511CP 2ml Screw Cap Microcentrifuge Tubes

- STSS-511CY 2ml Screw Cap Tube

- STSS-511CG Screw Cap Tubes 2ml

- STSS-511AM Amber Centrifuge Tubes

- STSS-509CNS 0.5ml Screw Cap Tube

- STSS-510CNS 1.5ml Screw Cap Tube

- STSS-511CNS Screw Cap Tube

- WMPB008 Pharma Pet Bottles

- WMPB015 HDPE Bottles For Pharmaceutical

- WMPB030 Wide Mouth HDPE Containers

- WMPB060 HDPE Wide Mouth Jars

- WMPB125 Pharmaceutical Plastic Bottles

- WMPB250 Plastic Bottle For Medicine Packaging

- WMPB500 Wide Mouth Polypropylene Jars

- WMPB1000 Bio Plastic Bottles

- WMPB008A Bio Pet Bottle

- WMPB015A Plastic Reagent Bottle

- WMPB030A HDPE Reagent Bottle

- WMPB060A Pharmaceutical Bottle

- WMPB125A Pharma Pet Bottle

- WMPB250A Pharma Plastic Bottle

- WMPB500A Plastic Pharmaceutical Bottles

- WMPB1000A Pharma Bottle Packaging

- NMPB008 Plastic Bottle For Pharmaceutical

- NMPB015 Small Plastic Pill Bottles

- NMPB030 Clear Pill Bottles

- NMPB060 Large Empty Pill Bottles

- NMPB125 Homeopathic Medicine Plastic Bottles

- NMPB250 Plastic Medicine Bottle

- NMPB500 Plastic Containers For Medicines

- NMPB1000 Plastic Drug Vials

- NMPB008A HDPE Medicine Bottle

- NMPB015A Pet Medicine Bottles

- NMPB030A Medical Plastic Bottles

- NMPB060A Plastic Liquid Medicine Bottles

- NMPB125A Plastic Tablet Bottles

- NMPB250A Amber Plastic Medicine Bottles

- NMPB500A Brown Plastic Medicine Bottles

- NMPB1000A Empty Plastic Medicine Bottles

What are you looking for?